NIOZ test location

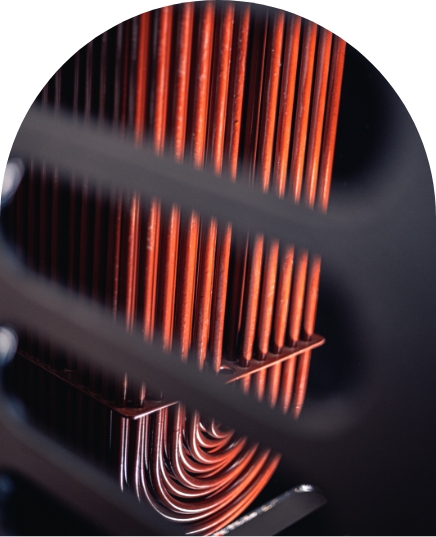

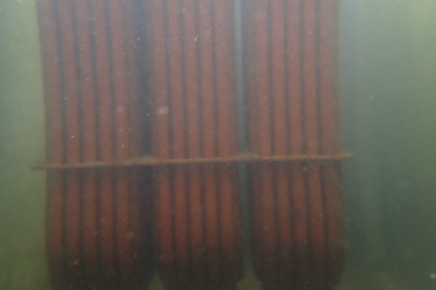

At the Yerseke location of the NIOZ (Dutch Institute for Marine Research) a set of testbassins has been used to determine the efficiency of ultrasound systems for the prevention of marine growth on boxcoolers. Coolers without ultrasound, coolers with conventional ultrasound and coolers with the GreenSonic® designed converters were exposed to exact the same conditions.